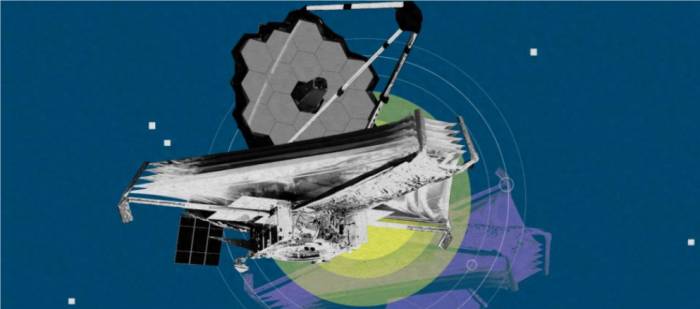

In January 2022, the National Aeronautics and Space Administration (NASA) is set to complete the 100 billion dollar James Webb Space Telescope's 1.6 million kilometer journey, but reaching its designated orbit is only part of this perilous voyage.

To prepare for observation, the spacecraft must be deployed in a complex manner. According to calculations by its engineers, there are as many as 344 ways it could fail.

A sunshield the size of a tennis court must be deployed perfectly, eventually resembling a giant, shiny kite beneath the telescope. The secondary mirror must swing downward to a perfect position, relying on three legs to secure it about 7.6 meters away from the primary mirror.

Finally, the primary mirror, composed of 18 hexagonal segments resembling a honeycomb, must self-assemble.

Three golden mirror sections must unfold from the sides of the telescope, embedding their edges into the 12 mirrors that have already been assembled together.The assembly process must be carried out in strict order for the telescope to function properly.

Karen Casey, Technical Director of Raytheon Company's Aerospace Defense Systems business, said: "That was a terrifying moment."

It is understood that Raytheon Company has developed the software to control the movement of the telescope and is now responsible for its operation.

Advertisement

During the telescope's deployment process, which lasted several days, engineers from Raytheon Company closely monitored its every move from Earth.

The telescope is located beyond the orbit of the moon, so far away that even the most powerful observation instruments cannot see it.But the telescope can transmit data back to Earth in real-time, and the software uses this data almost synchronously to render a 3D video of the unfolding process. It's like watching a thrilling movie.

The 3D video is the "digital twin" of the complex telescope: a model of the instrument created by a computer through the information provided by the instrument. Casey said, "This is a big change, and now we can see it."

In the early stages of the telescope's operation, the team watched the model nervously and finally breathed a sigh of relief when none of the 344 potential issues occurred.

Finally, the telescope entered its final form, looking as it should in space and on the screen. Since then, the telescope's "digital twin" has been continuously updating itself.

For Raytheon, the concept of building such a complex full-scale replica is not new, partly because of the company's work in the defense and intelligence fields. Compared to astronomy, digital twin technology is more popular in these fields.However, the James Webb Space Telescope is actually more complex than many systems, and the new advances made in the application of digital twins will now be fed back to Raytheon's military business.

Generally speaking, national security drives the development of science and technology, but this story is the exact opposite.

Dan Isaacs, Chief Technology Officer of the Digital Twin Consortium, said that space is the intersection of non-defense and defense technology, and digital twins are the "core of these collaborative efforts."

As this technology becomes more widespread, researchers are increasingly finding that digital twins are a productive member of the scientific community.

It helps humans operate the world's most complex instruments, while also revealing more information about the world itself and beyond the universe.8 billion data points

In 2002, Michael Grieves, a researcher focused on business and manufacturing, introduced the concept of "Digital Twin." He suggested that during the development of a physical object, the digital model of the physical product should be continuously updated.

However, the term "Digital Twin" actually comes from a NASA employee named John Vickers, who first used it in 2010 as part of the space agency's technology roadmap report.

Today, Grieves is the head of the Digital Twin Institute, and Vickers remains a technical expert at NASA.

With sensors attached to objects, the Internet of Things (IoT) connects the real world to the internet. Today, the number of these devices exceeds 15 billion, compared to only a few million in 2010.Currently, our computational capabilities are continuously increasing. Cloud services are more popular and powerful than they were a decade ago, allowing manufacturers of digital twins to scale up or down their models, or create more clones for experiments, without investing in a large amount of hardware.

Now, digital twins can also integrate artificial intelligence and machine learning to help understand the vast amount of data points captured every second.

Based on these factors, Raytheon decided to build a digital twin of the James Webb Space Telescope for the same reason it develops digital twins in the defense field: there is little room for error.

Kathy said, "This is a mission that cannot fail."

This digital twin model tracks 800 million data points of the real telescope every day, all of which are composed of 0s and 1s, forming a real-time video that is easier to monitor by humans than piles of numbers.The telescope team uses digital twins to monitor the observatory and predict the impact of changes such as software updates.

During testing of these, engineers use an offline copy of the digital twin, upload hypothetical changes, and then observe what happens next.

The group also uses the offline version to train operators and address a problem called IRL. Casey refused to disclose its nature. "We call it an anomaly," she said.

Science, Defense, and Other FieldsThe digital twin of a telescope is not the first space science instrument to have a "virtual brother." The digital twin of the "Curiosity" Mars rover has helped NASA solve its heat dissipation problem.

For the particle accelerator at CERN, the European Organization for Nuclear Research, digital twins have assisted in the development of detectors and monitoring of ventilation systems, among other things. The European Space Agency hopes to use Earth observation data to create a digital twin of the Earth itself.

At the Gran Telescopio Canarias, the world's largest single-mirror telescope, the scientific team began constructing a twin telescope about two years ago, even before they had heard the term.

At that time, the engineering lead, Luis Rodríguez, approached the observatory director, Romano Corradi. Corradi said, "He told us we should start linking things together."

Rodríguez suggested that they could learn principles from the industry. In industrial applications, machines regularly communicate with each other and with computers, monitor their own status, and automatically respond to these states.The team began to add sensors to convey information about the telescope and its environment. Coradi said that understanding the environmental conditions around the observatory is the "foundation of operating the telescope." These conditions include whether it will rain, how temperature affects the focus of the oscilloscope, and so on.

After the sensors provided data, they created a 3D model of the telescope to visualize these facts.

Rodriguez said: "This is a very obvious advantage for the staff operating the telescope. Managing the telescope has become easier. In the past, controlling the telescope was very difficult because it was very complex."

Now, the digital twin of the telescope has just started to receive data, but the team is working hard to adopt a more interpretative approach, using artificial intelligence to predict the behavior of the instrument.

Coradi said: "With the information in the digital twin, you can do something in the real telescope." Ultimately, they hope to have a "smart telescope" that can automatically respond to its situation.Koradi said that it was not until last year, when they attended an Internet of Things conference, that the team realized the thing they were building had a name.

He said: "We see that in the industry, rather than in the scientific community, there is a growing community where everyone is now doing these digital twins."

Of course, as demonstrated by particle accelerators and space agencies, this concept is quietly entering the field of science, but it is still firmly rooted in the business world.

Koradi said: "The interest in industry always precedes the interest in science." However, he believes that projects like theirs will continue to surge in the broader astronomical community.

For example, the responsible group for the planned Thirty Meter Telescope has called them to introduce this technology.The telescope will have a primary mirror composed of hundreds of small mirrors. Coradi said, "We were just anticipating some of the things that have happened in this industry."

The defense industry really likes digital twins. For example, the U.S. Space Force uses a digital twin to plan the Tetra 5 project, an experiment for refueling satellites.

In 2022, the U.S. Space Force also signed a contract with Slingshot Aerospace to create a space digital twin model, demonstrating what happens in Earth's orbit and preparing for events such as collisions.

Isaac gave an example where the Air Force sent a retired aircraft to a university so that researchers could map a "fatigue profile," an image of the aircraft's stress, strain, and load accumulation over time.

The digital twin made from this image can help identify parts that need to be replaced to extend the life of the aircraft or to design better aircraft in the future.Companies in the defense and science sector, especially those in the aerospace industry, are therefore at a significant advantage as they can transfer innovations from one sector to another.

For instance, the digital twin of the James Webb Space Telescope will have some relevance to Raytheon's defense projects, a company that is already developing digital twins for missile defense radar, air-launched cruise missiles, and aircraft.

Kathy says: "We can reuse parts of it elsewhere. (And) any satellite that tracks or sends commands could benefit from the work we have done on the James Webb Space Telescope."